This is the reason that Average total cost curve is U Shaped curve. This is because of the concept of diminishing marginal return which states that after some point, adding an additional factor of production will result in a smaller increase in output.

But now the catch is that this decline will not continue forever and after a certain level, the average cost starts to increase. But as we keep on increasing the quantity, average costs start to decline. This is because that fixed cost is now spread over 2000 units and per unit fixed cost is lower as compared to an earlier scenario.įor small quantity of output, as explained earlier, the total cost is higher. So if you see here, as we increase the number of cars, the average total cost per car dropped. Now, if we increase the number of cars, fixed cost will not change and only variation will happen in the variable cost Total variable cost per car is calculated as: all are fixed cost since these costs does not have direct linkage with the unit produced. But costs like plant, assembly line, equipment, R&D etc. all are variable costs because all of these costs will vary as per the number of cars the company is producing. So for them, costs like Steel, glass screens, number of tires, car seats, engines etc. Total Cost = Fixed cost + Total Variable CostĪverage Total Cost is calculated using the formula given belowĬompany ABC Inc.is working in manufacturing/assembling of Cars. Total Cost is calculated using the formula given below Total Variable Cost = Variable Cost per Pack * Number of Packs Total Variable Cost is calculated using the formula given below The company is producing 1000 on an average. Fixed Cost which they have invested in equipment etc. Suppose there is an FMCG company which is producing candy for kids.

Atc formula download#

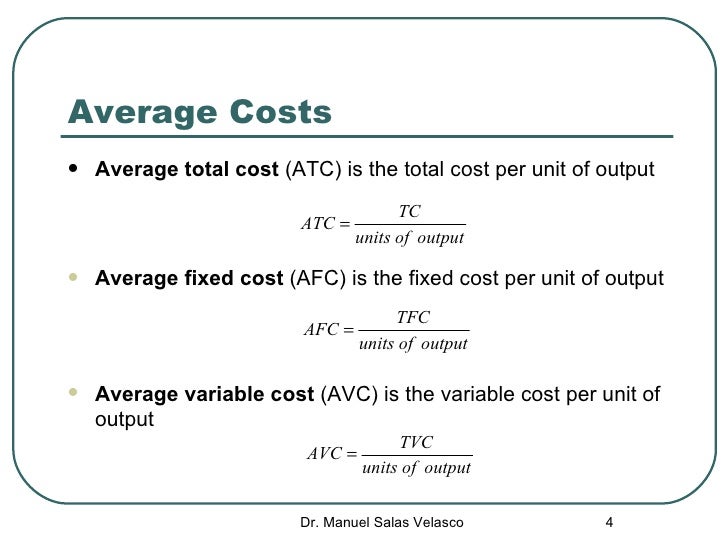

You can download this Average Total Cost Formula Excel Template here – Average Total Cost Formula Excel Template Average Total Cost Formula – Example #1 Let’s take an example to understand the calculation of Average Total Cost formula in a better manner. Examples of Average Total Cost Formula (With Excel Template) So as the unit produced keeps on increasing, per unit fixed cost will drop so as the average total cost. This cost is not related to how many unit businesses is going to produce. This due to the fact that when a business will start its production, they have to incur certain fixed cost like buying machinery, equipment etc. Total cost = Fixed cost + Total variable costĪverage total cost, during the initial stages of production, will be higher and will go down as we increase the number of units produced. It includes both Fixed cost (one time cost which is required to produce the goods but does not change with the output) and Variable cost (per unit cost to produce the goods which change as per the output) Here Total cost includes all the costs which are required to produce the goods. The FEMA P-58-2, Seismic Performance Assessment of Buildings, Volume 2 – Implementation Guide, Second Edition, provides detailed guidance on conducting performance assessments using PACT.Average Total Cost = Total Cost of Production / Number of Units Produced

Provides instructions on the use of PACT.

Atc formula manual#

Performance Assessment Calculation Tool User Manual Providing overall and performance group specific loss information obtained from the above calculations.Performing loss calculations including repair cost, downtime, and casualty estimates and.Gathering and organizing building information, fragility functions, and demand parameters.PACT provides three basic but integrated functions: It can accommodate results obtained from nonlinear response history analyses as well as simplified analyses. PACT provides a user-friendly platform for scenario-based, intensity-based, and time-based loss calculations. The Performance Assessment Calculation Tool (PACT) provided in Volume 3 is the computational companion to Volume 1. FEMA P-58, Volume 2, Appendix C presents a User Manual for PACT. An executable file (.exe) is provided to facilitate installation of the tool. An executable file consequence information in the referenced databases.

Atc formula update#

It includes a series of utilities used to specify building properties and update or modify fragility and consequence information in the referenced databases. PACT is an electronic calculation tool, and repository of fragility and consequence data, that performs the probabilistic calculations and accumulation of losses described in the methodology. Performance Assessment Calculation Tool (PACT)

0 kommentar(er)

0 kommentar(er)